What Should We Do When Need To Store The Coal Mining Scraper Conveyor For A Long Time?

Date:2020-02-09 Label:

Scraper Conveyor

Coal Mining Scraper Conveyor

Coal Conveyor

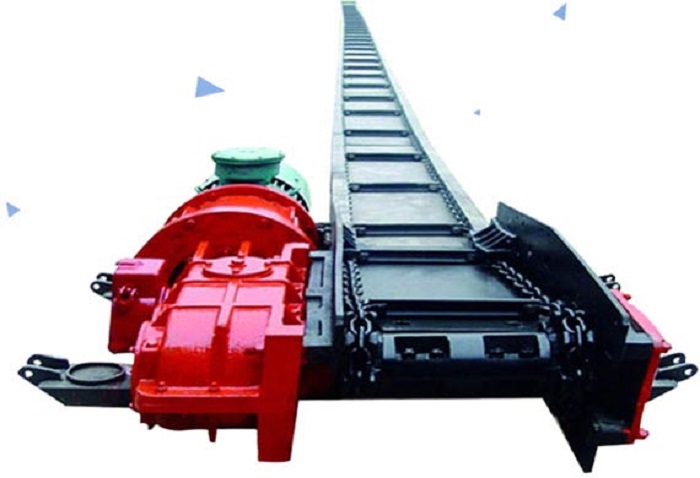

Coal mining scraper conveyor, which is a continuous conveying device for conveying loose materials by means of a moving scraper chain, should be protected from mechanical damage during its shelf life.All parts of the conveyor should be stored in a rain-proof, moisture-proof, anti-corrosive, clean, dry, and smoke-free environment. The temperature should be controlled between 5 ° C and 25 ° C. As far as possible, the conveyor parts should be stored in their original packaging. Electrical equipment and hydraulic parts should be stored on the warehouse shelves or stored in the original packaging. The rubber products should be stored in a heating warehouse, and should not be exposed to sunlight. The air must not contain alkaline, acid and other corrosive gases.

When the storage layer needs to be stored for a long time or the protective layer fails due to damage to the packaging of the parts, coal mining scraper conveyor parts should be re-rusted. The reducer should be drained of oil, filled with the same brand of lubricant, remove the vent plug, and replace the screw plug; during storage, rotate the input shaft of the reducer manually at a certain interval, at least should Rotate the output shaft of the reducer for one revolution; store it for more than two years, and replace the oil seal of the reducer before use. When the reducer and electric motor are stored, the cooling water should be drained cleanly.