Coal Conveyor Used In Coal Mining

Date:2024-09-12 Label:

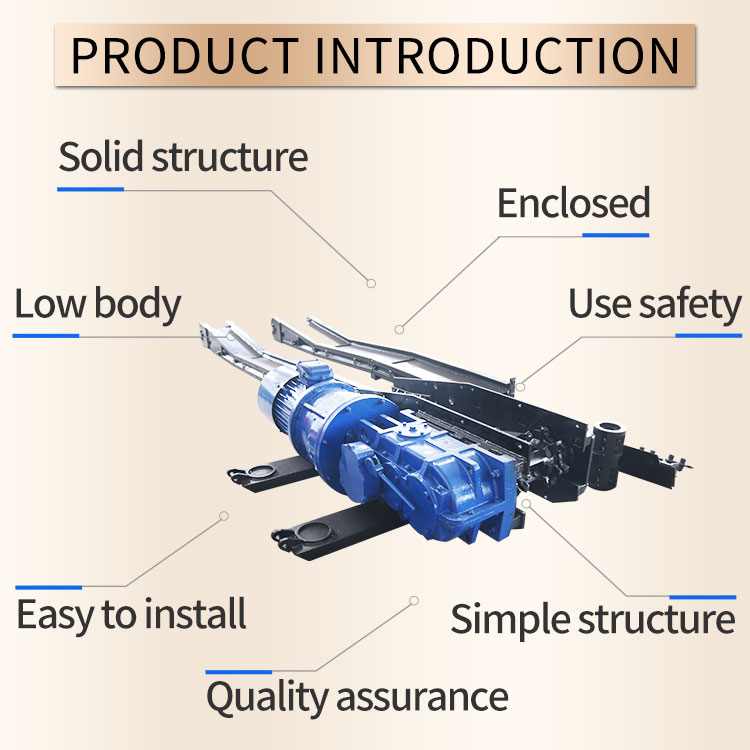

Coal Conveyor

Coal conveyors are crucial components in the coal mining industry, as they transport coal from the mining site to processing facilities or directly to the end-users. Here's an overview of their roles, types, and key considerations:

Roles and Importance

Efficiency:

Coal conveyors significantly speed up the process of moving coal compared to manual or other mechanical methods, increasing overall productivity.

Safety: They reduce the need for manual handling, which can be dangerous due to the weight and potential dust exposure of coal.

Cost-Effectiveness: Over time,

Coal conveyors can be more economical than alternative transportation methods, especially for large-scale operations.

Types of

Coal conveyors

Belt Conveyors: These are the most common type. They use a continuous belt made of material such as rubber, steel, or synthetic fabric to transport coal. They are ideal for long distances and high capacity.

Bucket Elevators: These are used for vertical lifting of coal. They consist of a series of buckets attached to a belt or chain. They are useful in situations where space is limited and vertical transport is necessary.

Pipe Conveyors: These conveyors transport coal within a closed pipe, which helps in reducing dust and spillage. They are suitable for challenging terrains and environments.

Chain Conveyors: Using chains instead of belts, these are often used for transporting coal over shorter distances or in environments where heavy loads are involved.

Shuttle Conveyors: These are used for moving coal horizontally and then shifting it to different locations, often within stockpiles or to different processing areas.

Key Considerations

Capacity and Speed:

Coal conveyors systems should be designed to handle the specific volume and speed requirements of the mining operation.

Durability: Given the harsh conditions, including heavy loads and abrasive coal,

Coal conveyors need to be built to withstand wear and tear.

Dust Control: Coal dust can be a significant issue.

Coal conveyors often need systems in place to minimize dust, such as enclosure systems or dust suppression sprays.

Maintenance: Regular maintenance is crucial to prevent breakdowns and ensure smooth operation. This includes checking for belt wear, alignment issues, and other potential problems.

Safety:

Coal conveyors should be equipped with safety features, including emergency stop buttons, guards, and sensors to prevent accidents and injuries.

Overall,

Coal conveyorsare essential for the efficient and safe handling of coal in mining operations, and choosing the right type and maintaining it properly can have a significant impact on the productivity and safety of the mining process.