Reasons for the wear resistance of the middle groove of the coal mining scraper conveyor after maintenance

Date:2020-09-05 Label:

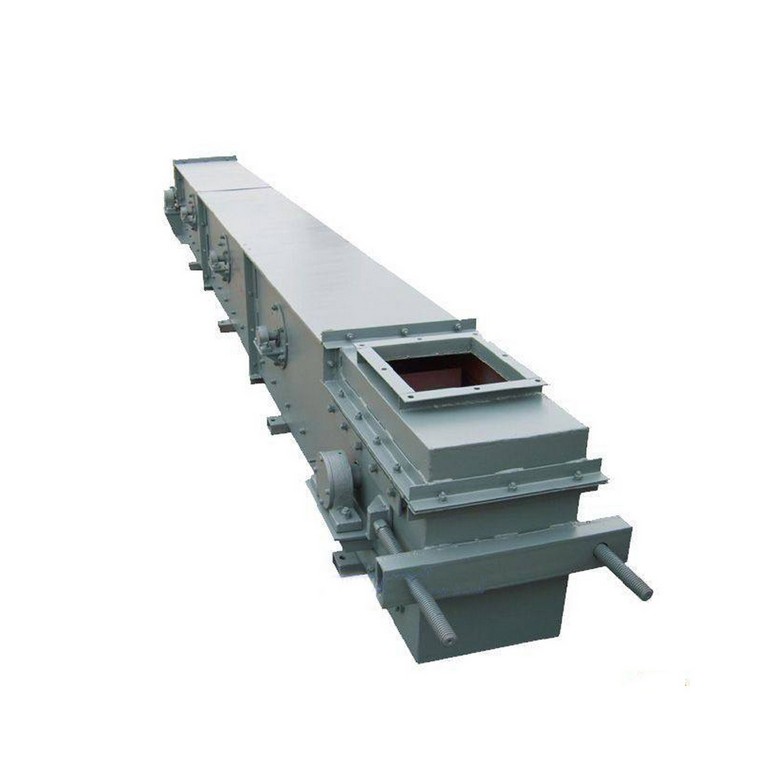

coal mining scraper conveyor

scraper conveyor

In order to save costs and achieve the purpose of saving expenditure and reducing consumption, many coal mines usually carry out re-maintenance and surfacing welding on the middle groove of the coal mining scraper conveyor that is not too severely worn. The editor will take you to understand that the middle groove of the coal mining scraper conveyor is so wear-resistant after surfacing repair.

Rust and scale removal process

Affected by the harsh environmental conditions underground, the middle groove of the coal mining scraper conveyor will rust during use in coal mines. In order to reduce the influence of impurities during welding, the welding part of the middle groove of the coal mining scraper conveyor should be Carry out rust removal and paint protection for the middle groove of the unused coal mining scraper conveyor.

Surfacing process

Warm up. Because the surfacing process requires temperature, before surfacing, in order to reach a certain temperature, the construction part of the middle groove and the welding materials must be heat treated.

Through the above wear-resistant process treatment, the service life of the middle groove of the coal mining scraper conveyor can be effectively extended, which is the "secret" for increasing the wear resistance of the middle groove after surfacing repair.