How to determine the conveying length of coal mining scraper conveyor

Date:2020-10-24 Label:

coal mining scraper conveyor

scraper conveyor

The conveyor line of the coal mining scraper conveyor is adaptable and flexible. The length of the line depends on the need. The coal mining scraper conveyor has low power consumption. Since the material and the conveyor belt have almost no relative movement, not only the running resistance is small (about 1/6-1/8 of the coal mining scraper conveyor), but also the wear and breakage of the cargo are small, and the productivity is high. These are all conducive to reducing production costs.

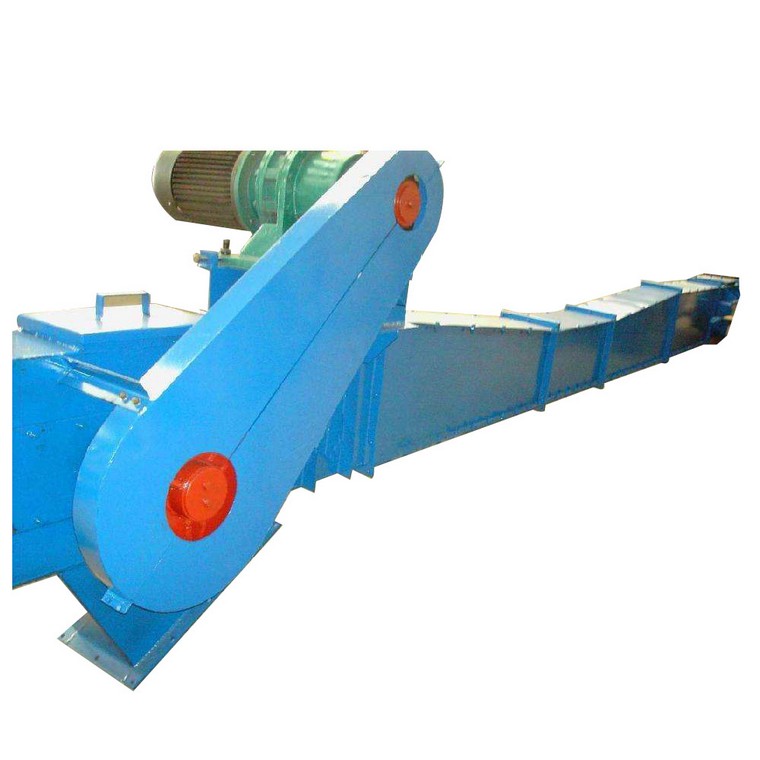

The coal mining scraper conveyor can fetch materials in the roadway below the stockpiles of the coal storage yard, and can also mix the different materials when needed. The material can be simply discharged from the conveyor head, or it can be discharged at any point along the length of the coal mining scraper conveyor belt through a plough unloader or a mobile unloader. It is composed of coal mining scraper conveyor belt, driving device, roller, frame, cleaner, tensioning device and braking device.

According to the requirements of the technological process, the coal mining scraper conveyor can flexibly receive materials from one or more points. It can also discharge to multiple points or several sections. When feeding materials to the coal mining scraper conveyor belt at several points at the same time (such as the conveyor under the coal bunker of the coal preparation plant) or feeding the coal mining scraper conveyor belt through the uniform feeding equipment at any point along the length of the scraper conveyor, the scraper conveys The machine becomes a main conveying trunk line.

The conveyor belt 1 is wound around the driving roller 2 and the tail reversing roller 3 to form an endless endless closed belt. The upper and lower rain conveyor belts are supported on the upper roller 4 and the lower roller 5 respectively. The tensioning device 6 ensures the tension required for the normal operation of the conveyor belt.