How To Reduce The Broken Chain Problem Of Coal Mining Scraper Conveyor

Date:2019-11-27 Label:

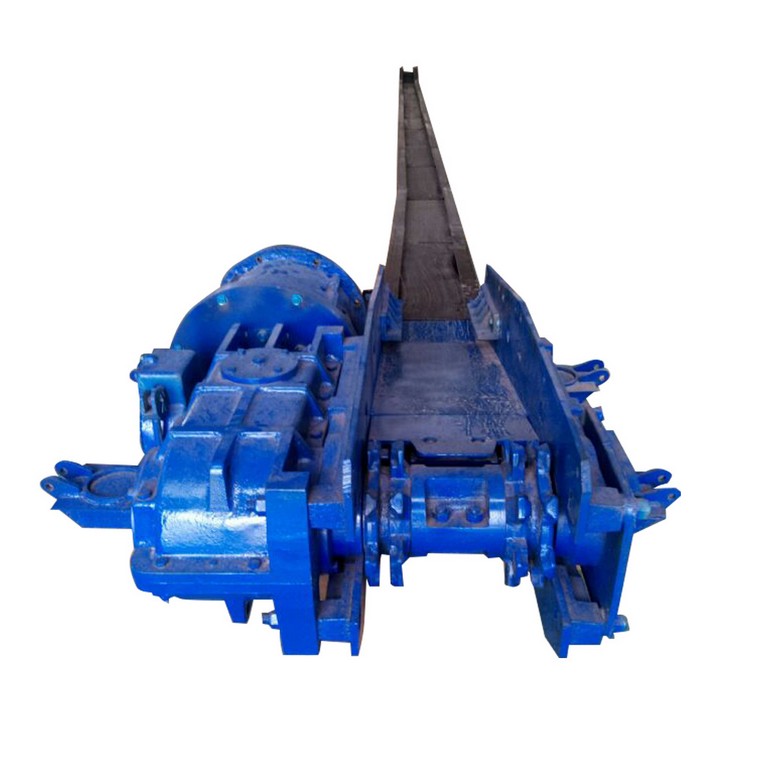

Scraper Conveyor

Coal Mining Scraper Conveyor

The chain is one of the main accessories of the coal mining scraper conveyor. The function of the chain is mainly combined with the scraper to form the traction member of the scraper conveyor, which drives the coal to move along the chute until the head is unloaded. However, in the process of coal transportation, chain breaking of the scraper conveyor often occurs. According to statistics, a third of the scraper conveyor failures are caused by broken chains. Therefore, it is very important to reduce the problem of broken chains and ensure the safe operation of the scraper conveyor.

Enterprises should install strictly in accordance with the requirements of installation quality standards. The installer should tighten the scraper bolts to prevent the chain and scraper from being reversed. The head, middle and tail of the coal mining scraper conveyor must keep a straight line. At the same time, the main sprocket, driven sprocket, and chain should be completely matched to avoid accelerating the wear of the chain and the chute due to uneven forces on the two chains. The scraper is stuck due to the wear of the chain and the chute, which causes the chain to break.

During the operation, the workers also need to pay attention to the stress of the chain during the operation of the scraper to avoid over-tightening the chain and whether the coal mining scraper conveyor is worn, corroded, deformed and fatigued. After using the chain for a period of time, it should be removed and turned 90 degrees before using it. This can change the position of the horizontal and vertical links, and extend the life of the chain by changing its vulnerable parts. In addition, the staff should regularly use the detector to check the hidden cracks on the scraper chain, and replace the damaged scraper and chain ring in time to ensure the normal operation of the scraper chain.

Before the scraper works normally, relevant personnel should clean up the coal scale, vermiculite and other debris in the driveway of the machine to make the ground as flat as possible and keep the working surface straight. When using the scraper, the staff should regularly clean up the accumulated waste in the scraper. When the chain is too loose or too tight during operation, the staff should apply initial tension to the scraper chain after a period of use to make it stretch elastically. Through the intelligent monitoring of the chain tension, the most suitable initial tension of the specific scraper chain can be calculated to make it in the optimal state, and the damage to the chain caused by non-constant load is reduced.