How to clean the vibration motor of the chain scraper conveyor?

Date:2020-05-21 Label:

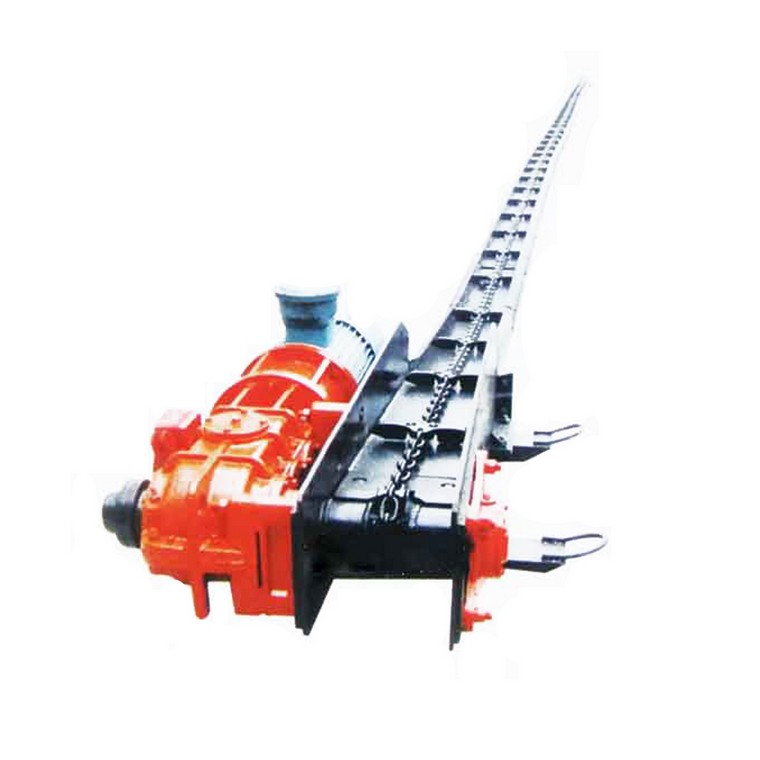

Scraper Conveyor

Chain Scraper Conveyor

Scraper Chain Conveyor

Chain scraper conveyor have been widely used in metallurgy, building materials, power, chemical industry, cement, ports, docks, coal, mining, grain and oil, food, feed and other industries and departments. The scraper chain conveyor has the following requirements for materials: loose density of materials: p = 0.2 ~ 2.5t / m3. Material temperature: The general model is suitable for the material temperature less than 120 ° C; the temperature of the hot material conveying material is 100 ~ 450 ° C, and the instantaneous material temperature is allowed to reach 800 ° C. Moisture content: The moisture content is related to the material's material content and viscosity. Generally, it should be loosened after being squeezed into a mass.

After long-term use of the vibration motor of the chain scraper conveyor, the bearings hardened with soft dry oil or anti-rust paste should be immersed in hot engine oil at 100-200 ℃, clamp the bearing with pliers, and clean the oil on the bearing with a brush . Soft dry oil or anti-rust paste is melted by heating to 100-200 ℃, and it is easy to wash out from the gap of the bearing. When cleaning the centrifugal spherical bearings of the old motor or imported motor of the scraper conveyor, the balls, bead holders, and inner ring should be laterally turned from the outer ring and then immersed in hot oil. When cleaning the short cylindrical roller bearings The roller, bead holder, inner ring and outer ring should also be disengaged. When cleaning with hot oil, the temperature of the oil should not exceed 20 ° C. The bearings installed on the shaft of the chain scraper conveyor mainly rely on the method of spraying oil or spraying with an oil gun. The oil stains that are easily cleaned are first used with kerosene and then gasoline; the oil stains that are difficult to clean are first heated with 100-200 ℃ Rinse the engine oil or spray with an oil gun, and then clean it with gasoline.