Small maintenance details of chain scraper conveyor

Date:2020-06-19 Label:

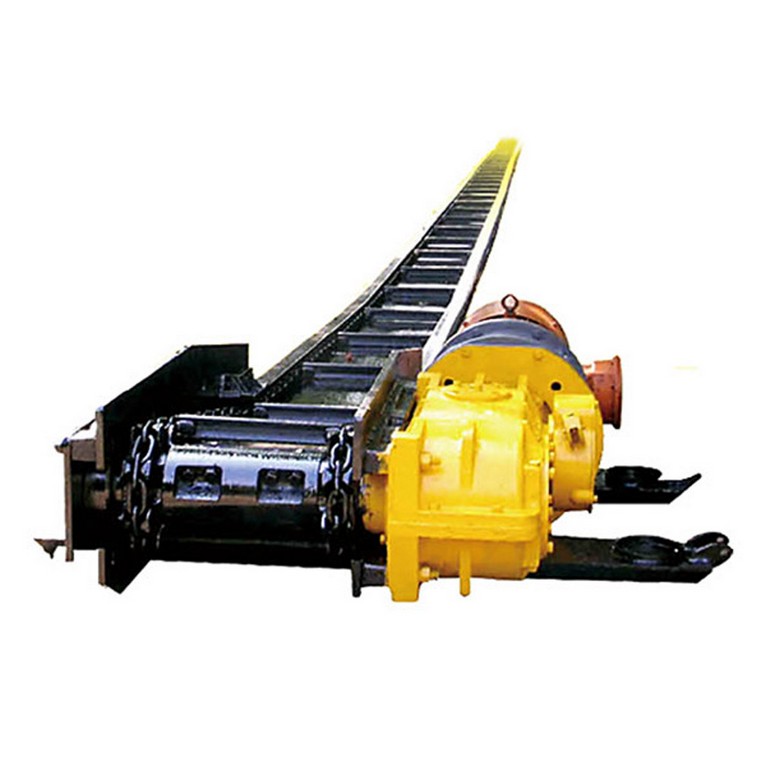

Scraper Conveyor

Chain Scraper Conveyor

Scraper Chain Conveyor

The chain scraper conveyor is a continuous running precision conveying equipment. When the center distance of the sprocket is less than half a meter, it can deviate by one millimeter. If the center distance is more than half a meter, we can make him the maximum deviation of two millimeters. If it exceeds this range, it will shorten the service life of the chain scraper conveyor. For the same reason, many small deviations of the chain scraper conveyor will cause the chain scraper conveyor to "fold life". For example, the chain should have a good elasticity, which is the most standard. If it is too loose, the chain scraper conveyor will be easily off the chain when it is running, causing damage. On the contrary, if it is too tight, it will increase the waste of power and cause damage to the components. During commissioning, it can be pressed down or lifted from the middle of the chain, and the center distance between the two is most suitable between 23%. After the chain scraper conveyor is used for a period of time, when many parts are difficult to adjust accurately, you can first remove the chain link. Here, it must be remembered that it must be an even number, the locking piece is inserted outside, and the opening of the locking piece should face The opposite direction of rotation.

In the process of maintaining the scraper chain conveyor, we must also strictly check the new and old status of each component and update it in time. So as not to damage other components. If the sprocket teeth of the scraper chain conveyor are worn, but it is not time to throw it away, then turn it over and use it, which can extend the use time and save costs.