Study the specific content of the drive system of coal mining scraper conveyor

Date:2020-02-24 Label:

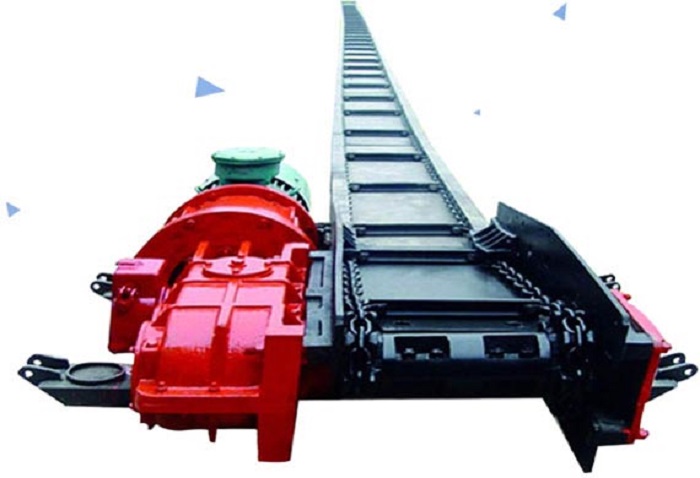

coal mining scraper conveyor

scraper conveyor

Coal mining scraper conveyor is responsible for the task of transporting coal, providing the running track for the shearer, and providing the fulcrum for the hydraulic support. Frequent start during work and heavy load start not only make it difficult to start, but also waste a lot of power. In view of this problem, we have studied the drive system of the scraper conveyor. The specific content includes the following aspects:

First, the load characteristics of coal mining scraper conveyor were studied. The reasons for difficult starting and frequent overloads were analyzed.

Secondly, the feasibility analysis of the variable frequency drive model is carried out. Analyze the cause of large low-speed torque ripple under the traditional direct torque control system.

Finally, the feasibility of the program is verified, and the hardware circuit of the low-power inverter in the laboratory is debugged.

Conclusion: The failure interruption protection design of coal mining scraper conveyor is essential for the system design, and the main purpose is to protect the power switching device and the motor. The main circuit is mainly designed for the rectifier circuit, filter circuit, energy braking circuit, inverter circuit and drive circuit; the control circuit is a control system built with the DSP2407 chip; the protection circuits mainly include Undervoltage protection and short circuit protection, IGBT overcurrent, overvoltage protection, motor overheat protection, overload protection and phase failure protection.