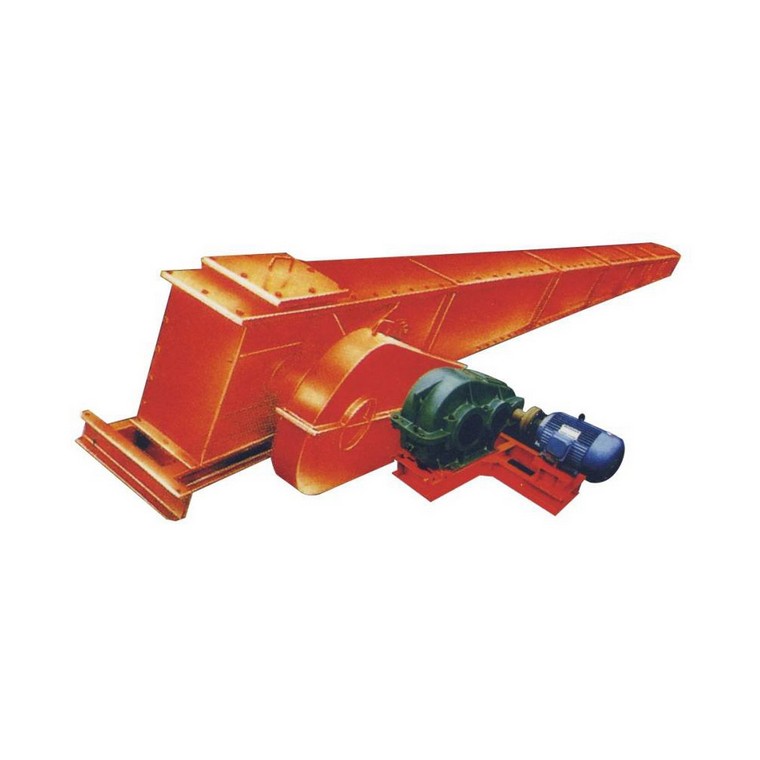

The formation of a complete coal mining scraper conveyor structure requires different

Date:2020-08-12 Label:

coal mining scraper conveyor

scraper conveyor

Coal Conveyor

The formation of a complete coal mining scraper conveyor structure requires the use of different components, and different structural components play different roles. Then, the mobile sprocket composed of the coal mining scraper conveyor structure is one of its components. What role does it play in the work?

The movable sprocket composed of the coal mining scraper conveyor structure usually adopts the concave tooth type. Compared with the convex tooth sprocket, it is more adaptable to the domestic round chain. It can ensure that the chain will not be worn after the chain is severely worn and the circumference is not worn. Increased wear and tear greatly extends the chain replacement cycle.

Corresponding chain tension adjustment adopts worm gear deceleration and self-locking tensioning mechanism, which saves labor, is convenient to operate, and ensures that both sides are tensioned at the same time. At the same time, the high-strength round mining chain of the coal mining

scraper conveyor is used as the conveyor chain, which has a large bearing capacity and abrasion resistance. Due to the characteristics of material transfer, the return chain and scraper are separated from the material, thereby avoiding a sudden increase in the amount of feed. Increased and blocked the squeegee accident caused by the engine room.

Not only that, the overload protection device is also installed in the structure of the coal mining scraper conveyor. When the chain is overloaded, it will automatically stop and send an alarm signal. In order to reduce the wear of the scraper and the chain of the coal mining scraper conveyor, the basalt cast stone lining is not only much longer than the life of the metal substrate, but also has less frictional resistance than the metal substrate.

The coal mining scraper conveyor is equipped with a broken chain alarm device, which can detect broken chains and broken chains in time, automatically stop and send out an alarm signal. In addition to the special carrying drive mechanism, it not only has a good force, saves space, but also is easy to install and maintain.

The model and specifications of the coal mining scraper conveyor are determined according to the larger throughput required by the process. After selecting the selected coal mining scraper conveyor, whether it is horizontal or vertical during the working process, when the material enters the closed slot of the machine from the feed port, the loose material is formed under the action of the scraper thrust and the gravity of the material Enough internal friction.